- inelastic_modelsThe material objects to use to calculate stress and inelastic strains. Note: specify creep models first and plasticity models second.

C++ Type:std::vector<MaterialName>

Controllable:No

Description:The material objects to use to calculate stress and inelastic strains. Note: specify creep models first and plasticity models second.

ADComputeMultipleInelasticStress

Compute state (stress and internal parameters such as plastic strains and internal parameters) using an iterative process. Combinations of creep models and plastic models may be used.

Description

ADComputeMultipleInelasticStress computes the stress and a decomposition of the strain into elastic and inelastic components for a series of different inelastic material models (e.g. creep and plasticity) which inherit from ADStressUpdateBase. This material supplies material properties with all derivatives required to form an exact Jacobian. By default finite strains are assumed. The elastic strain is calculated by subtracting the computed inelastic strain increment tensor from the mechanical strain increment tensor.

(1) Mechanical strain, , is considered to be the sum of the elastic and inelastic (e.g. plastic and creep) strains.

This class uses the finite incremental strain formulation as a default. Users may elect to use a small incremental strain formulation and set perform_finite_strain_rotations = false if the simulation will only ever use small strains. This class is not intended for use with a total small linearize strain formulation.

ADComputeMultipleInelasticStress is designed to be used in conjunction with a separate model or set of models that computes the inelastic strain for a given stress state. These inelastic models must derive from the ADStressUpdateBase class.

ADStressUpdate Material ModelsAll of the inelastic material models that are compatible with ADComputeMultipleInelasicStress follow the nomenclature convention of StressUpdate as a suffix to the class name.

ADComputeMultipleInelasticStress can accomodate as few as zero inelastic models (in which case the algorithm from ADComputeFiniteStrainElasticStress is applied) to as many inelastic material models as is required by the physics. If more than one inelastic material model is supplied to ADComputeMultipleInelasticStress, it is recommended that all of the inelastic models inherit from the same base class.

Multiple Inelastic Models

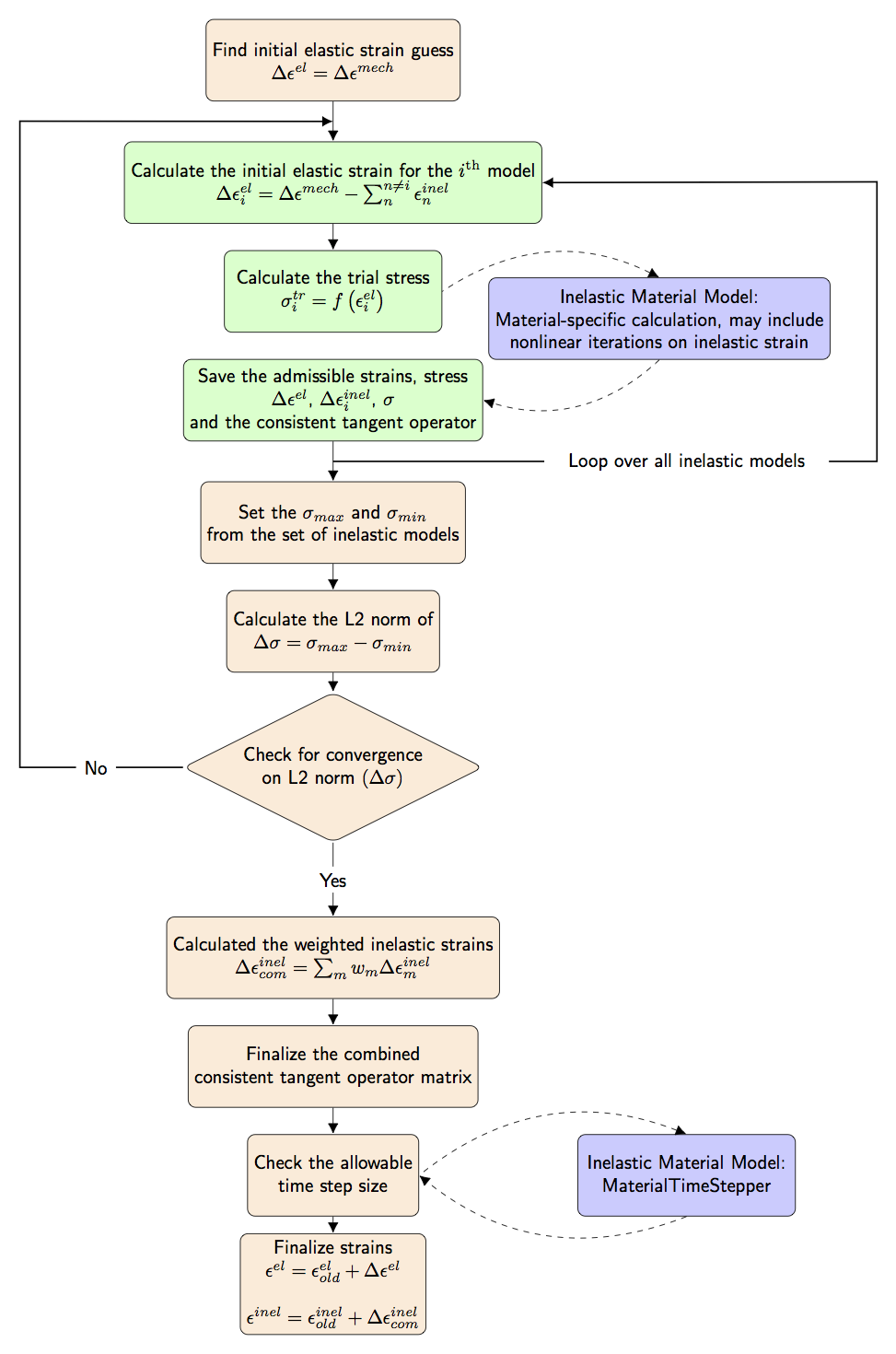

Figure 1: The ADComputeMultipleInelasticStress algorithm for calculating the strains and stresses for multiple inelastic material models. (Note that computation of the consistent tangent operator is not performed in this version of the class. An exact Jacobian is guaranteed through automatic differention)

The algorithm used to compute the stress for multiple inelastic models is shown in Figure 1.

When multiple inelastic models are given, ADComputeMultipleInelasticStress iterates over the specified inelastic models until the change in stress is within a user-specified tolerance.

Inner Iteration over Inelastic Models

The inner iteration over the multiple inelastic material models is shown in the green components in Figure 1.

When each inelastic model is evaluated, a trial stress is computed using the current elastic strain, which is the total mechanical strain minus the current summation of inelastic strain for all inelastic models. This trial stress can be expressed as

(2)

where is the elasticity tensor for the material.

The inelastic material model, represented by the blue element Figure 1, is then called. The inelastic material model calculates the inelastic strain increment necessary to produce an admissible stress, as a function of the trial stress. The total inelastic strain increment is updated for each model's contribution. The details of this calculation vary by model and can include the effects of plasticity or creep.

The elastic and inelastic strain increments and the stress are returned to ADComputeMultipleInelasticStress from the inelastic material model.

Outer Iteration over Stress Difference

After each inelastic model is called to compute an update to the stress tensor, the minimum and maximum values of each component of the stress tensor, over the course of those iterations, are stored to two tensors denoted as and , respectively. An norm of the difference of these two tensors is then computed as

(3)

The norm of the stress difference is compared to the absolute and relative tolerances to determine if the solution from the combined inelastic material models is converged

(4)

where is the norm from the very first outer iteration over all of the inelastic material models. The solution will not converge if the outer iteration loop, shown in the top half of Figure 1, exceeds the maximum number of iterations set by the user.

Once convergence on the stress is obtained, the calculation of the inelastic strains is finalized by by applying a weighting factor, as shown in Figure 1. This weighting factor has a default value of unity.

Material Time Step Size Limitations

Prior to calculating the final strain values, the algorithm checks the size of the current time step against any limitations on the size of the time step as optionally defined by the inelastic material models. As described in the Material Time Step Limiter section, the time step size involves a post processor to ensure that the current time step size is reasonable for each of the inelastic material models used in the simulation.

At the end of the alogrithm, the final value of the elastic and inelastic strain tensors are calculated as shown in the last element of Figure 1.

Single Inelastic Model

ADComputeMultipleInelasticStress can also be used to calculate the inelastic strain and the stress when only a single inelastic material model is provided.

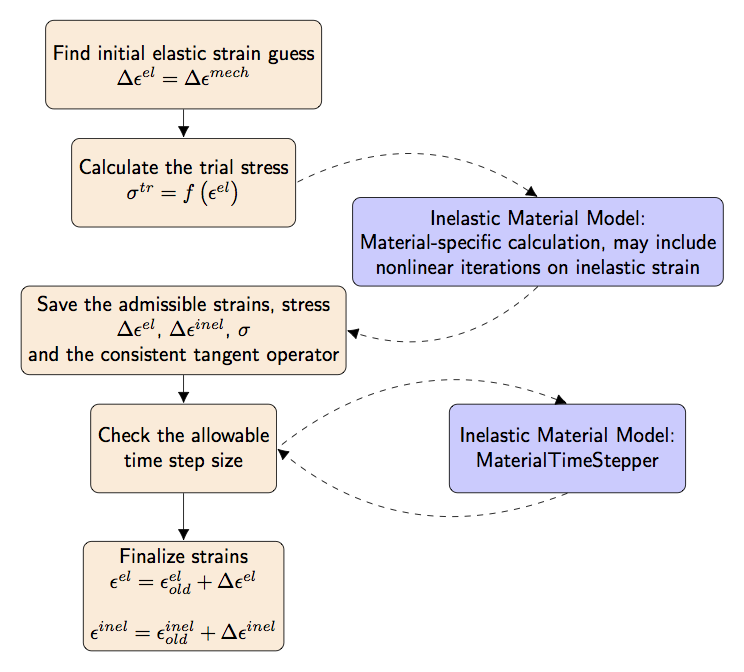

Figure 2: The optimized algorithm for calculating the strains and stress in the case when only a single inelastic material model is specified.

The algorithm, shown in Figure 2, used for a single inelastic material model is an optimized version of the multiple materials algorithm. With no need to iterate over multiple inelastic models, both the inner and outer iterations from Figure 1 are removed from the algorithm in Figure 2.

The initial elastic strain increment guess is assumed to be the initial mechanical strian increment, and the trial stress for the single inelastic model is calculated from that elastic strain increment as in Eq. (2). These stress and strain values are passed directly to the inelastic material model.

The material model computes the admissible stress and strain states, as indicated by the blue element in Figure 2. The maximum size of the allowable time step is then optionally calculated by the inelastic material model, as described in the section below on the Material Time Step Limiter. At the conclusion of the algorithm, the value of the elastic and inelastic strain states are updated as shown in Figure 2.

Cycle Through One Inelastic Model per Time Step

ADComputeMultipleInelasticStress also includes an option to run a series of inelastic models in a rotating fashion such that only a single inelastic model is run on a timestep. This option uses the same algorithm as in Figure 2 to determine the strains and stress value based on the rotated single inelastic model. A separate method is then employed to propagate the strain and stress values to the other inelastic material models for storage as old material property values.

Other Calculations Performed by StressUpdate Materials

The ADComputeMultipleInelasticStress material relies on two helper calculations to aid the simulation in converging. These helper computations are defined within the specific inelastic models, and only a brief overview is given here. These methods are represented within the blue inelastic material model boxes in Figure 1 and Figure 2. For specific details of the implementations, see the documentation pages for the individual inelastic StressUpdate materials.

Material Time Step Limiter

In some cases, particularly in creep, limits on the time step are required by the material model formulation. Each inelastic material model is responsible for calculating the maximum time step allowable for that material model. The MaterialTimeStepPostprocessor finds the minumum time step size limits from the entire simulation domain. The postprocessor then interfaces with the IterationAdaptiveDT to restrict the time step size based on the limit calculated in the previous time step.

Example Input Files

The input settings for multiple inelastic material models and a single inelastic model are similiar, and examples of both are shown below.

Multiple Inelastic Models

For multiple inelastic models, all of the inelastic material model names must be listed as arguements to the inelastic_models parameter. The inelastic material blocks must also be present.

[Materials]

[./elasticity_tensor]

type = ComputeIsotropicElasticityTensor

block = 0

youngs_modulus = 1e3

poissons_ratio = 0.3

[../]

[./creep_plas]

type = ComputeMultipleInelasticStress

block = 0

tangent_operator = elastic

inelastic_models = 'creep plas'

max_iterations = 50

absolute_tolerance = 1e-05

combined_inelastic_strain_weights = '0.0 1.0'

[../]

[./creep]

type = PowerLawCreepStressUpdate

block = 0

coefficient = 0.5e-7

n_exponent = 5

m_exponent = -0.5

activation_energy = 0

[../]

[./plas]

type = IsotropicPlasticityStressUpdate

block = 0

hardening_constant = 100

yield_stress = 20

[../]

[]

Single Inelastic Model

For a single inelastic material model the input syntax is simply condensed

[./stress]

type = ComputeMultipleInelasticStress

inelastic_models = 'isoplas'

block = 1

[../]

and only a single inelastic material model is included in the input. This example includes the max_inelastic_increment parameter which is used to limit the time step size.

[./isoplas]

type = IsotropicPlasticityStressUpdate

yield_stress = 5e6

hardening_constant = 0.0

relative_tolerance = 1e-20

absolute_tolerance = 1e-8

max_inelastic_increment = 0.000001

[../]

Input Parameters

- absolute_tolerance1e-05Absolute convergence tolerance for the stress update iterations over the stress change after all update materials are called

Default:1e-05

C++ Type:double

Controllable:No

Description:Absolute convergence tolerance for the stress update iterations over the stress change after all update materials are called

- base_nameOptional parameter that allows the user to define multiple mechanics material systems on the same block, i.e. for multiple phases

C++ Type:std::string

Controllable:No

Description:Optional parameter that allows the user to define multiple mechanics material systems on the same block, i.e. for multiple phases

- blockThe list of blocks (ids or names) that this object will be applied

C++ Type:std::vector<SubdomainName>

Controllable:No

Description:The list of blocks (ids or names) that this object will be applied

- boundaryThe list of boundaries (ids or names) from the mesh where this object applies

C++ Type:std::vector<BoundaryName>

Controllable:No

Description:The list of boundaries (ids or names) from the mesh where this object applies

- combined_inelastic_strain_weightsThe combined_inelastic_strain Material Property is a weighted sum of the model inelastic strains. This parameter is a vector of weights, of the same length as inelastic_models. Default = '1 1 ... 1'. This parameter is set to 1 if the number of models = 1

C++ Type:std::vector<double>

Controllable:No

Description:The combined_inelastic_strain Material Property is a weighted sum of the model inelastic strains. This parameter is a vector of weights, of the same length as inelastic_models. Default = '1 1 ... 1'. This parameter is set to 1 if the number of models = 1

- computeTrueWhen false, MOOSE will not call compute methods on this material. The user must call computeProperties() after retrieving the MaterialBase via MaterialBasePropertyInterface::getMaterialBase(). Non-computed MaterialBases are not sorted for dependencies.

Default:True

C++ Type:bool

Controllable:No

Description:When false, MOOSE will not call compute methods on this material. The user must call computeProperties() after retrieving the MaterialBase via MaterialBasePropertyInterface::getMaterialBase(). Non-computed MaterialBases are not sorted for dependencies.

- constant_onNONEWhen ELEMENT, MOOSE will only call computeQpProperties() for the 0th quadrature point, and then copy that value to the other qps.When SUBDOMAIN, MOOSE will only call computeQpProperties() for the 0th quadrature point, and then copy that value to the other qps. Evaluations on element qps will be skipped

Default:NONE

C++ Type:MooseEnum

Controllable:No

Description:When ELEMENT, MOOSE will only call computeQpProperties() for the 0th quadrature point, and then copy that value to the other qps.When SUBDOMAIN, MOOSE will only call computeQpProperties() for the 0th quadrature point, and then copy that value to the other qps. Evaluations on element qps will be skipped

- cycle_modelsFalseAt time step N use only inelastic model N % num_models.

Default:False

C++ Type:bool

Controllable:No

Description:At time step N use only inelastic model N % num_models.

- damage_modelName of the damage model

C++ Type:MaterialName

Controllable:No

Description:Name of the damage model

- declare_suffixAn optional suffix parameter that can be appended to any declared properties. The suffix will be prepended with a '_' character.

C++ Type:MaterialPropertyName

Controllable:No

Description:An optional suffix parameter that can be appended to any declared properties. The suffix will be prepended with a '_' character.

- extra_stress_namesMaterial property names of rank two tensors to be added to the stress.

C++ Type:std::vector<MaterialPropertyName>

Controllable:No

Description:Material property names of rank two tensors to be added to the stress.

- internal_solve_full_iteration_historyFalseSet to true to output stress update iteration information over the stress change

Default:False

C++ Type:bool

Controllable:No

Description:Set to true to output stress update iteration information over the stress change

- max_iterations30Maximum number of the stress update iterations over the stress change after all update materials are called

Default:30

C++ Type:unsigned int

Controllable:No

Description:Maximum number of the stress update iterations over the stress change after all update materials are called

- perform_finite_strain_rotationsTrueTensors are correctly rotated in finite-strain simulations. For optimal performance you can set this to 'false' if you are only ever using small strains

Default:True

C++ Type:bool

Controllable:No

Description:Tensors are correctly rotated in finite-strain simulations. For optimal performance you can set this to 'false' if you are only ever using small strains

- prop_getter_suffixAn optional suffix parameter that can be appended to any attempt to retrieve/get material properties. The suffix will be prepended with a '_' character.

C++ Type:MaterialPropertyName

Controllable:No

Description:An optional suffix parameter that can be appended to any attempt to retrieve/get material properties. The suffix will be prepended with a '_' character.

- relative_tolerance1e-05Relative convergence tolerance for the stress update iterations over the stress change after all update materials are called

Default:1e-05

C++ Type:double

Controllable:No

Description:Relative convergence tolerance for the stress update iterations over the stress change after all update materials are called

Optional Parameters

- control_tagsAdds user-defined labels for accessing object parameters via control logic.

C++ Type:std::vector<std::string>

Controllable:No

Description:Adds user-defined labels for accessing object parameters via control logic.

- enableTrueSet the enabled status of the MooseObject.

Default:True

C++ Type:bool

Controllable:Yes

Description:Set the enabled status of the MooseObject.

- implicitTrueDetermines whether this object is calculated using an implicit or explicit form

Default:True

C++ Type:bool

Controllable:No

Description:Determines whether this object is calculated using an implicit or explicit form

- seed0The seed for the master random number generator

Default:0

C++ Type:unsigned int

Controllable:No

Description:The seed for the master random number generator

Advanced Parameters

- output_propertiesList of material properties, from this material, to output (outputs must also be defined to an output type)

C++ Type:std::vector<std::string>

Controllable:No

Description:List of material properties, from this material, to output (outputs must also be defined to an output type)

- outputsnone Vector of output names where you would like to restrict the output of variables(s) associated with this object

Default:none

C++ Type:std::vector<OutputName>

Controllable:No

Description:Vector of output names where you would like to restrict the output of variables(s) associated with this object